- Mobile:+86 17561919576

- WhatsApp:+86 17561919576

- Email:business@cexcasting.com

3D Rapid Prototype

CEX SERVICES

REQUEST A FREE QUOTE

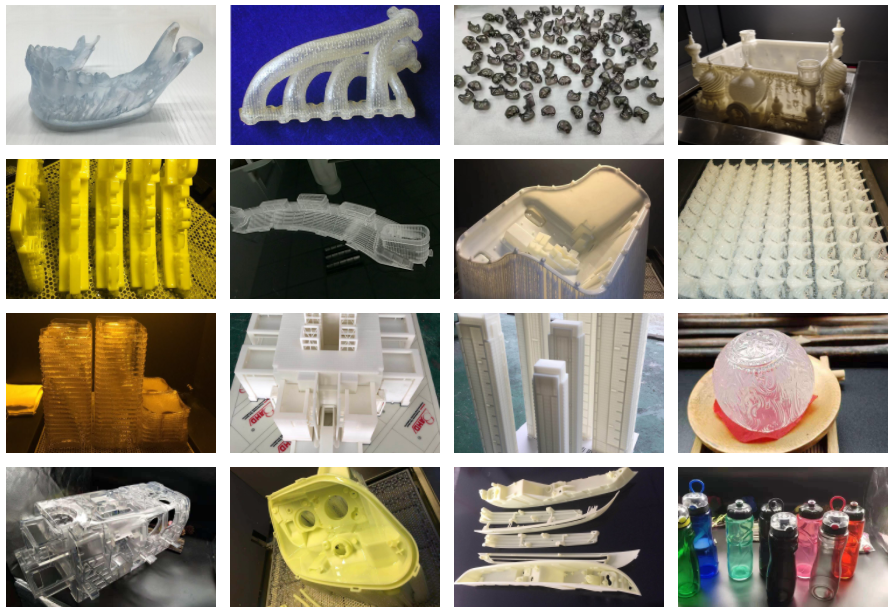

CEX company owned the resin, metal, PP and other material printers, which can provide prototype 3D printing and 3D scanning services for 3D printing area, just like aerospace, automotive, medical, electronics and other industries. 3D rapid prototyping processes is usually achieved by using digital technology material printers. It is often used to make models in mold manufacturing, industrial design and other fields, and then gradually used in the direct manufacturing of some products. There are already parts printed using this technology. The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction, automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, guns, and other fields.

3D printing Workshop in CEX

what is rapid prototyping?

3D printing (3DP) is a kind of rapid prototype technology, also known as additive manufacturing, it is a kind of digital model file as the basis, the use of powdered metal or plastic and other bondable materials, printed layer by layer ways to construct the technology of objects.

Advantage of Rapid Prototyping

- The most prominent advantagesof 3D printing rapid prototyping technology is that it can directly generate parts of any shape from computer graphics data without machining or any molds, thereby greatly shortening the product development cycle, improving productivity and reducing production costs. Compared with the traditional technology, the cost is reduced by abandoning the production line, and the material waste is greatly reduced.

- 3Dprototype printingcan produce shapes that cannot be produced by traditional production technology, so that people can design aircraft wings or heat exchangers more effectively.

- With a good 3D printing design concept and design process, 3D printing technology can also simplify the manufacturing process, and produce a single item quickly, efficiently and cheaply. Compared with machine-made parts, the printed product is 60% lighter and equally strong.

Metal 3d Printing Rapid Prototyping

Metal 3D Print Prototyping changes the original design method of metal parts, making the output products, components and tools lighter, achieving more functions, and reducing the number of assemblies. Through high-precision metal manufacturing solutions, the integration of integrated software, metal additive technology, certified materials and expert application support is equivalent to one, which can save time, save costs, and manufacture lightweight parts.

FS271M can use isolation work gloves to operate the equipment cavity in the closed state to prevent the operator from inhaling metal dust or causing safety accidents when cleaning and adjusting the sintered workpiece in the cavity, preventing the danger of dust explosion, and ensuring personal safety. At the same time, the inert gas injected into the cavity will be monitored by the pressure monitoring system in real time. Through the intelligent pressure relief device, it will automatically open when the cavity reaches a certain pressure. According to the safety needs, there are also safety mechanical exhaust holes in the equipment to ensure The pressure can be safely relieved in special circumstances.

Nylon Fast Prototyping 3D Printing

Nylon printing has a wide range of applications. It can produce high-precision conceptual models, functional prototypes, master molds and molds, optimize your design, simplify work processes, and bring innovative products to achieve faster development. It brings a wide range of benefits to industrial designers and engineers. HT1001P is currently a nylon additive manufacturing solution with a print format of 1000mm, which will provide users with unprecedented continuous production capacity. The ultra-large molding cylinder of 1000×500X450mm can realize the integrated molding of large products and the mass production of small products. HT1001P has high temperature sintering ability, and can print E-print PA6, PA12 and other materials with sintering temperature below 225C, making the product performance more excellent.

FDM Prototypage Rapide

FDM (Fused Deposition Modeling) 3D printer has very good and rich functions, it can make durable parts according to your CAD files. These parts are very robust and can be used as advanced conceptual models, functional prototypes, manufacturing tools and production components. Engineers only need to load different files and materials to produce various products. No traditional machining process can do this.

Light Curing Molding Threed Printing

Light curing (SLA is a high-speed, high-precision 3D printing technology. UV laser and liquid UV-curable photopolymer-“photosensitive resin” are used to print parts. The laser beam is controlled to scan on the resin surface to make the resin liquid The surface is cured to form a cross-sectional layer film of the scanned part. After curing one layer, cover a layer of liquid resin on the newly formed layer film, and continue to scan, so that it is cured and combined on the cross-section of the part formed by the previous curing. So reciprocating, It grows layer by layer to print out complete three-dimensional parts.

Multi-Material Composite Rapid Prototyping 3D Printing

The Polyjet3 printer enables professional designers, engineers, educators and healthcare professionals to create opportunities and solve problems accurately, quickly and realistically. The powerful advantage comes from PoyJet technology. The curable photosensitive resin can generate very fine layers and smooth surfaces, intricate details and bright colors. The versatility of Polyjet technology is based on widely available material properties and a series of 3D printers, which can be adapted to different budgets and application scenarios. Regardless of the industry, Polyjet technology can provide powerful capabilities to solve problems and create opportunities.

Prototyping 3D Items We Developed