- Mobile:+86 17561919576

- WhatsApp:+86 17561919576

- Email:business@cexcasting.com

Mould Development

CEX SERVICES

REQUEST A FREE QUOTE

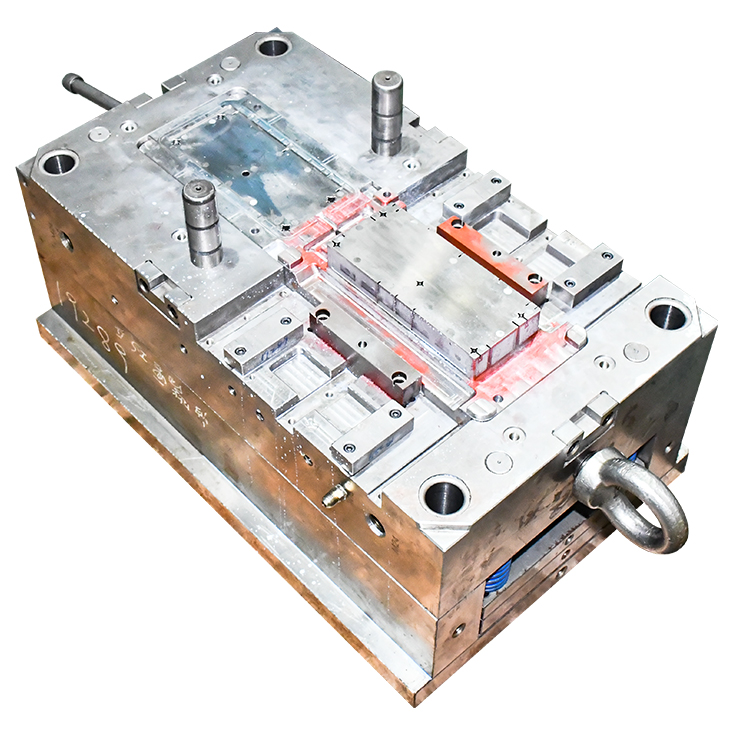

China Mould Making Suppliers for Plastic Injection Precision Moulds & Die Casting Dies

CEX company specialize in making mould since 1995, has rich experience, generally can meet customer’s demands. What is mould? Mould, various moulds and tool used in industrial production to obtain desired products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods. In short, define die, is a tool used to make molded objects. This tool is composed of various parts, and different dies are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the “Mother of Industry”.

Mold Characteristic

Under the action of external force, the blank becomes a tool with a specific shape and size. It is widely used in punching, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, engineering plastics, rubber, ceramics and other products by compression moulding or injection moulding. The mould has a specific contour or cavity shape, and the contour shape with a cutting edge can be used to separate the blank according to the contour shape (punching). The shape of the inner cavity can be used to obtain the corresponding three-dimensional shape of the blank.

About dies, is generally includes two parts: a movable mould and a fixed die (or a convex mould and a concave mould), which can be separated or combined. The parts are taken out when they are separated, and the blanks are injected into the mould cavity to form when they are closed. The die is a precision tool with a complex shape and can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mould production is one of the important signs of the level of mechanical manufacturing.

Types of Mould

According to the processing object and processing technology, it can be divided into:

- Die moulds for processing metal.(Such as steel casting mould, iron casting moulds, cast iron moulds, aluminum casting moulds, aluminum mould, )

- Process non-metal and powder metallurgy moulds. Including plastic moulds (such as two-color moulds, compression moulds and extrusion moulds), rubber moulds and powder metallurgy moulds.

According to the structural characteristics, it can be divided into:

- flat punching mould

- cavity mould with space.

According to the different materials,it can be divided into:

- Hardware moulds, including stamping mould (such as stamping mould, punching moulds, bending moulds, deep drawing moulds, turning moulds, shrinkage moulds, undulating moulds, bulging moulds, cheap plastic moulds), forging dies(such as forging moulds, upsetting moulds), extrusion moulds, diecasting mould, forging moulds and etc.

- Non-metallic moulds, including plastic moulds, inorganic non-metallic moulds, sand moulds, vacuum moulds, and paraffin wax moulds.

Among them, with the rapid development of polymer plastics, plastic molds are closely related to people’s lives. Plastic mould can generally be divided into: injection moulding moulds, extrusion moulding die, gas-assisted moulding moulds, etc.

What is Mould Made Out Of?

<300℃ zinc alloy Cr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10.

300~500℃ aluminum alloy, copper alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2.

500~800℃ Aluminum alloy, copper alloy, steel titanium GH130, GH33, GH37.

800~1000℃ Titanium alloy, steel, stainless steel, nickel alloy K3, K5, K17, K19, GH99, IN100, ЖC-6NX88, MAR-M200, TRW-NASA, WA.

>1000℃ Nickel alloy, copper-based alloy mold, cemented carbide mold.

Metal Moulds We Developed