- Mobile:+86 17561919576

- WhatsApp:+86 17561919576

- Email:business@cexcasting.com

Aluminum Die Casting

aluminum Die Casting in cEX

CEX has more than 20 years of experience in aluminum die casting. We own 160-1100T die casting machines in our plant, and the most significant parts we could manufacture are up to 22kg.

We have the advantage that we do the manufacturing of the casting molds ourselves. The production efficiency of die-casting is high, and aluminum die-casting parts can be made in complex shapes, with precise dimensions, clear contours, high surface quality and strength, and hardness.

Therefore, Aluminum High-Pressure Die Casting Products are widely used and rapidly developing. The output of aluminum alloy die casting components is now very large, and then zinc alloy die casting parts.

What is Aluminum Die Casting

When we talk about die casting, one of the first things that come to mind is HPDC or High-Pressure Die Casting. The HPDC is a complex process that forces molten metal inside a sealed mold cavity to ensure the perfect shape and size. The method also uses extreme pressure to ensure the mold solidifies without any issues. This process is primarily done in a hydraulic machine to harness its extreme compressive power.

Once it is ensured that the liquid metal inside the mold is fully solidified, the die is released. After that, the die-cast mold cavity is removed in the following process cycle.

You will be surprised to know that the molten metal injection in this HPDC process takes only a fraction of a second. The average metal injection in High pressure die casting is usually under 90ms. And the moderate pressure that is applied in this casting process is around 1000 bar.

A forceful press holds molten metal inside a tightly closed metal die cavity as it cools and hardens during the high-pressure die casting process. The die is unlocked, opened, and the casting is ejected when the metal has solidified.

After removing the casting, the die is closed and locked for the following cycle. The metal injection into the die cavity is finished in a split second. Extremely high pressure is frequently used when the molten metal is still contained in the die.

Due to the high pressure, any trapped gas is compressed, and more metal is fed into the cavity to compensate for the metal’s shrinkage during solidification.

Our Available Die Casting Process

- Aluminum high pressure die casting

- Zinc high pressure die casting

- Aluminum squeeze die casting

Die Casting Machines

Die casting equipment types are divided into cold chamber die casting machines and hot chamber die casting machines.

In our factory, we use cold die casting machines to offer the most excellent result.

Our available die casting machine sizes including: 160T, 200T, 280T, 400T, 600T, 800T, 1100T.

Die casting machines types are divided into cold chamber die casting machines and hot chamber die casting machines.

In our factory, we use cold die casting machines to offer the most excellent result.

Other Machining Equipment

Here is a list of the other machine process equipment we use,

- CNC Machining center

- CNC turning

- CNC lathes

- electrical pulse

- Line Cutting

- Milling

- Drilling

- Grinding

Die Casting Material We Use

A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7/

For Squeeze Casting, we use, A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6.

Die Casting Surface Treatment

It’s not necessarily the end of the process once your part has been cast. For their part, many industrial enterprises decide to spend money on die-casting surface treatment. Adding exterior finishes to die casting can dramatically boost the quality and worth of your product by giving it extra qualities that you or your consumers may find appealing, even though a surface finish is not necessary for die casting.

Here is a list of die-casting surface treatments we offer to our clients,

- Sand blasting

- Trimming

- Deburring

- Polishing

- Shot blasting

- Tumbling

- Powder coating

- Chrome

- Zinc

- Electrophoresis

- Passivation

- Chemical coating.

Die Casting Part Drawing Software

In the die casting sector, we rely on gear, including design software applications, to assist us in achieving what we need. There are software tools available that can be helpful with the die casting procedure. With the aid of design, these programs help us bring our ideas to life and can help us create achievable objectives.

The software we use including: Assistance Pro e, Solid work, UG, AUtO CAD, CATIA.

Why Choose Us

- 1. One-stop service for aluminum die casting products. This includes everything from product design > Die Casting in house tooling> pressure Die cast Process > CNC Machining > post surface finish

- 2. With more than 20 years manufacture and export experience, right now 90% of our products are for Export

- 3. In house mold and tooling, which could make sure a shorter leading time and better control the quality.

- 4. IS9001 Certified with strict Quality Control System

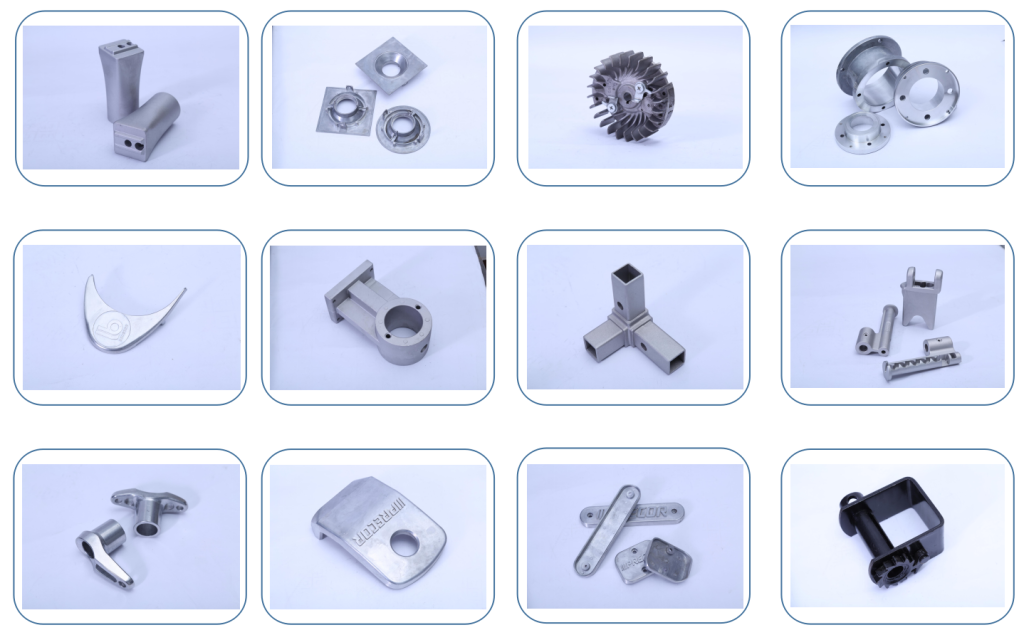

HPDC Items we developed

Final Thoughts

High-pressure die casting is becoming more and more popular every day in light of all of this. When it comes to finding the best high-pressure die-casting manufacturer, CEX Casting has got your back. To ensure that you receive nothing less than the most dependable and cost-effective solution for your particular demands, we provide top-of-the-line aluminum die casting process.

Get in touch with us today through our contact page, and enjoy the best die casting manufacturing you can ever imagine.