- Mobile:+86 17561919576

- WhatsApp:+86 17561919576

- Email:business@cexcasting.com

Squeeze Casting

Squeeze Casting Process in CEX

Our Squeeze Casting Facilities

CEX started to research and develop squeeze casting process from 2015. As a China leading squeeze casting manufacturer, we have patented squeeze casting process and equipment(300t-1100t) and one squeeze casting manufacturing base.

From the mold design, to the process parameters determination and product refinement, all these steps reflect the rich experience and wisdom of our engineers. The products we have developed have been used in various fields and have helped many customers to improve the mechanical properties of their products and significantly reduce their production costs.

Our Squeeze Casting Capability

- Equipment: 300t~1100t aluminum squeeze casting machine

- Material we use: A356, A380, A319, AlSi10Mg, AlSi9Mg, etc.

- Part weight: 50g~20kg

- Maximum size: 1.2m*0.8m

- Wall thickness: 4mm-25mm

- Tolerance: blank ±0.2mm, ±0.01mm after machining

- Heat treatment: T5, T6

Mechanical Property we could achieve:

- Tensile strength: 220-240MPa

- Yield strength: 260-320MPa

- Hardness: 80-90Hb

- Elongation: 4-10%

What is Squeeze Casting Process?

Squeeze casting, also known as liquid die forging, is types of casting process in which molten metal solidifies under pressure within closed dies positioned between the plates of a hydraulic press.

The pressure applied and the instant contact of the molten metal with the die surfaces produces a rapid heat transfer, which yields a pore-free, fine-grained casting with mechanical properties similar to those of a wrought product.

The squeeze die casting process is easily automated to produce near-net to net shaped, high-quality casting products.

Types of Squeeze Die Casting

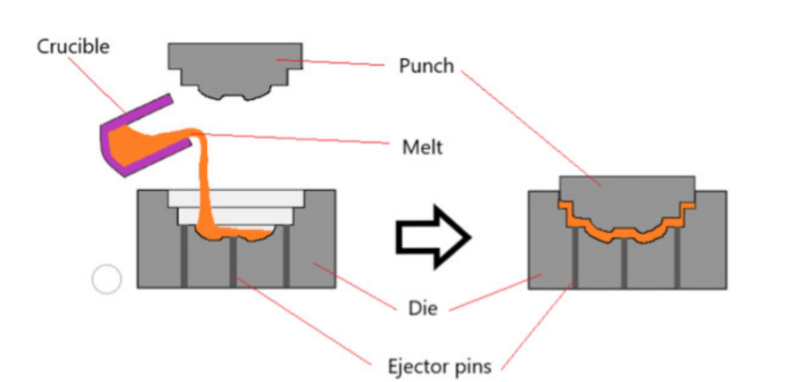

There are two types of squeeze casting processes: direct squeeze casting and indirect squeeze casting. The difference between the two types is how the high pressure applied to the molten metal.

Direct Squeeze Casting

Direct squeeze casting is a process in which the molten metal is poured directly into the mold cavity and pressure is introduced when the top punch is lowered into the bottom die.

This process is much like forging and that is why squeeze casting is also called liquid forging.

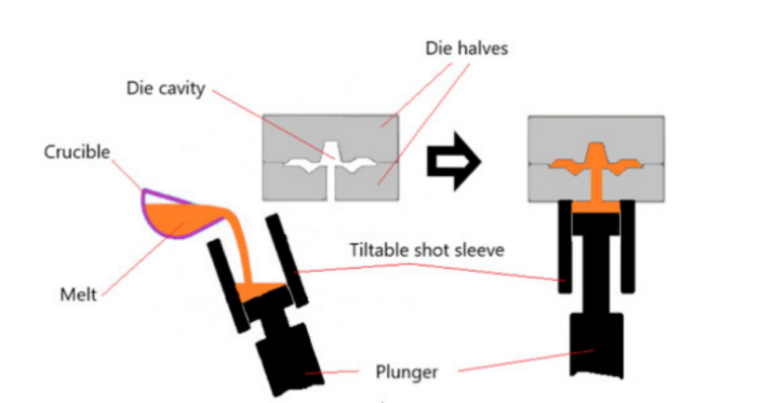

Indirect Squeeze Casting

Indirect squeeze casting is a process in which the molten metal is injected into the cavity from a plunger.

The pressure is applied by the plunger in the indirect squeeze casting.

Squeeze Die Casting Process Characteristics

The squeezing die casting process combines the advantages of casting and forging processes and has been widely used to produce quality castings.

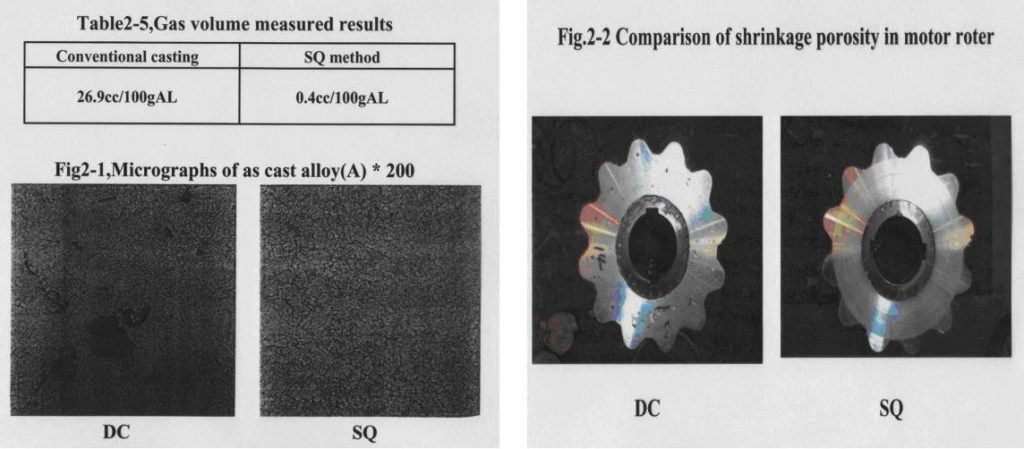

Because of the high pressure applied during the solidification, porosities caused by both gas and shrinkage can be prevented or eliminated.

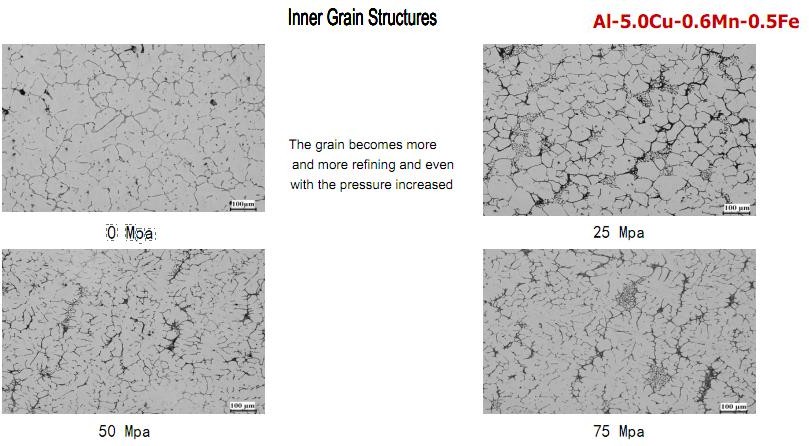

The cooling rate of the casting can be increased by applying high pressure during solidification, since contact between the casting and the die is improved by pressurization, which results in fine-grained structures.

1) Refined inner grain structures

2) Less gas and shrinkage porosity—Die Casting VS Squeeze Casting

Mechanical Preperties of Squeeze Castings

The biggest advantage of squeeze casting process is that the castings could be heat treated to achieve improved mechanical properties.

After T6, the mechanical property of the squeeze casting parts could be much higher.

Mechanical property comparison of the squeeze casting parts from different materials:

Note: Density 2.72g/cm³, tested pieces cut from casting parts. The data from the test bar will be higher.

Material | Tensile Strength Mpa | Yeild Strength Mpa | Hardness HB | Elongation % |

AISi9Mg | 240 | 160 | 80 | 3 |

A356 | 260 | 180 | 80 | 5 |

A356.2 | 300 | 220 | 90 | 7 |

Al-Ti alloy | 320 | 230 | 100 | 9 |

6061-T6 | 330 | 240 | 110 | 10 |

7075-T6 | 500 | 300 | 160 | 11 |

Squeeze Casting Process Advantages

- Good roughness similar to die casting & precision casting.

- Parts are made with high-accuracy like die casting & precision casting.

- No additional material costs and extra machining, better than forging.

- Can be T6 treated, better than die casting, and similar to forging.

- Parts have a high sealing property.

- High mechanical properties similar to forging, and better than investment casting or sand casting.

squeeze casting vs forging/investment casting/hpdc/low pressure die casting:

Items | Squeeze casting | Froging | Investment Casting | High Pressure Casting | Low Pressure Casting |

Surface | Fine | Fine | Bad | Fine | Medium |

Roughness | Ra3.2~1.6 | Ra3.2~1.6 | Ra6.3~3.2 | Ra3.2~1.6 | Ra6.3~3.2 |

Inside | Fine Grain & Compact microstructure | Fine Grain & Compact microstructure | Coarse grain&Loosen microstructure | Inhomogeneous grain &Loosen microstructure | Coarse grain&Loosen microstructure |

Heat Treatment | T6 | T6 | T6 | — | T6 |

Structure Level | Complex structre | Simple structre | Complex structre | Complex structre | Simple structre |

Froming Accuracy | High | Medium | Medium | High | Low |

Extra Machining | Minor | More | More | Minor | More |

Production Efficiency | High | Low | Low | High | Low |

Mechanical Properties | Same or close to forging | Highest | Medium | Low | Low |

Squeeze Casting Process Applications

Application | Parts |

Automobile Stressed Parts | Automobile Piston, AI- alloy or Almag wheel hub, Beam(cross beam), Knuckle, Lower arm, Brake caliper, Engine mounting, gearbox, Air compressor connectin rod |

Pressure parts/Air tight Parts | Air conditioning compressor turbine disk, Cylinder, Front and rear cover, Steering valve housing, Oil Pump, Manifold, Fuel distribution pipe, Brake block, Clutch cylinder |

Wear resistance parts | Shift Fork, Pump Casing, Rocker arms, Caterpillar board, Air compressor piston and swashplate, Aluminum composite brake hub |

Motorcycle Stressed parts | AI-alloy or Almag wheel hub, Upper and lower connecting plate, Gearbox housing, Rear hanger, Crank, Frame body, Joint, Frame joint, Direction axis |

Motorcycle pressure and wear parts | Aluminum piston, Shock absorber, Disc brake pump body |

Electrical Parts/Power Parts | Disk drive housing,Electrical spindle bushing, Electrical compression ring, Sonar shel, Hotplate, Computer parts, Rotors, Crimping clamp, Suspensin Clamp, Parralle groove calmp |

New energy vehicles | Electric automobile parts, Hybrid Power automobile parts, Bumpers, Body shell, Body framing |

Advanced field | Military parts, Aerospace accessories, Aircraft Accessories, Optical frame shell, Medical equipments accessories, Fitness equipment accessories |

Others | Marine Propellers, Pneumatic instrument housing, Pressure cooker and cooker equipments parts, Furniture accessories, Valve body, Valve Accessories, Garden tool parts, Fan blades, ect. |

Squeeze Casting Product We Developed

CEX casting is China leading squeeze casting company. Our Squeeze Casting Service Helped Many Companies To Improve The Mechanical Properties Of Different Parts.Those squeeze cast products have better mechanical characteristics than conventionally cast Parts because of their higher density, finer scale of grain and more homogeneous microstructure.

Replaces casting steel to give a lighter weight.

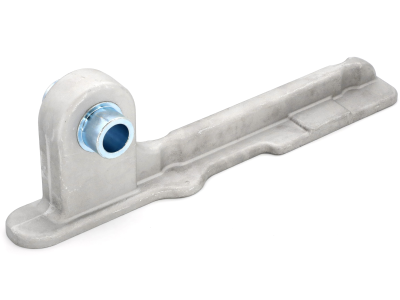

Part Name: Steering Knuckles Trailer Connector

Material: A356.2

Heat Treatment: T6

Unit Weight: 2.25kg

Unit Weight by Steel: 4.92kg

Weight reduced by 54%, passes 100W Bench Test

Replaces hot forging for some complex parts, reduces machining steps to save costs.

Part Name: Electric Scooter Folding Part

Material : A356.2

Heat treatment : T6

Reduces machining process, saves at least 40% of the costs.

Replaces traditional die casting and improves safety performance (50% strength increase).

Part Name : Tent Folding Part

Material : A356.2

Heat Treatment : T6

Strength 50% higher than traditional HPDC to give better support over longer distances.

No gas holes or shrinkage inside to meet high resistance and air tightness requirements.

Part Name : Valve parts

Material : A319

Heat Treatment : No Need

No porosity pits,dents and scratches on entire surface.

For more application, you can cilick here to get the whole Squeeze Castings Case Study document.

Our Squeeze Casting Equipment

- 280T- 1100T Squeeze Casting Equipment

- 4 Sets of CNC Machining Center

- 5 Sets of Precision Engraving Machine for Mold

- 50 Sets of Other Assistance Equipment

Our Squeeze Casting Quality Control Method

ISO9001& IATF 16949 system control of the entire production process.

Advanced quality inspection instruments and experienced quality inspectors

- Three-coordinate detectors

- Leak tester

- Two-dimensional scanners

- Hardness detector

- Tensile testers

- X-Ray detector