- Mobile:+86 17561919576

- WhatsApp:+86 17561919576

- Email:business@cexcasting.com

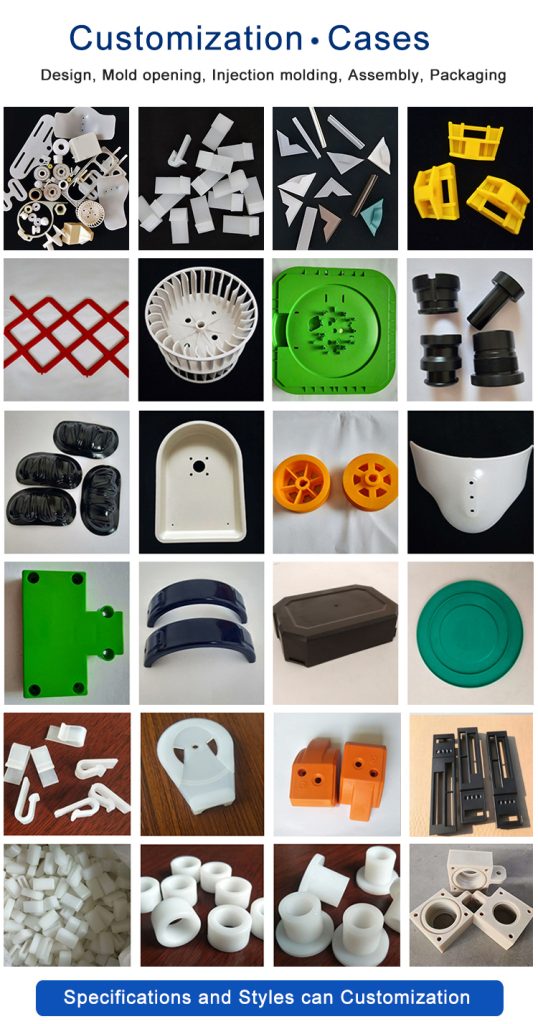

Plastic Injection Molding

CEX SERVICES

REQUEST A FREE QUOTE

China Custom Plastic Injection Molding Export and Manufacturers Sales Customized OEM Precision Injection Moulding Machine Products For Agricultural/ Medical/ Household/ Electronics/ Automotive Equipment

CEX has 90T-850T plastic injection molding equipments, largest custom plastic molding parts of injection we could manufacture is 5kg , any new developing parts needed welcome asking us for quotation. Injection molding, also known as injection moulding, is a molding method that combines injection and molding. At a certain temperature, the completely melted plastic material is stirred by a injection moulding screw, injected into the mold cavity with high pressure, and cooled and solidified to obtain a molded product. This method is suitable for mass production of parts with complex shapes and is one of the important processing methods. The process of injection moulding step by step can be roughly divided into the following 6 stages: Mold clamping, injection, pressure keeping, cooling, mold opening, and product removal. By repeating the above process, products can be produced periodically in batches. The molding of thermosetting plastics and rubber also includes the same process, but the barrel temperature is lower than that of thermoplastic injection molding, and the injection pressure is higher. The mold is heated. After material be injected, it needs to undergo a curing or vulcanization process in the mold, and then release the film while it is hot .

Plastic Injection Molding Process

Plastic injection molding , insert injection moulding , overmolding injection molding, thermoforming,injection blow molding process,extrude molding

Plastic Moulding Processes Characteristic

- The combination of easy formability and flexibility of resin and rigidity, strength and heat resistance of metal can be combined to make complex and exquisite injection molding machine parts.

- In particular, using the combination of the insulation of resin and the conductivity of metal, the molded products made can meet the basic functions of electrical products.

- The pre-molding combination of multiple inserts makes the post-engineering of product unit combination more rational.

- Insert products are not limited to metals, but also cloth, paper, wires, plastics, glass, wood, coils, electrical parts, etc.

- For rigid molded products and bending plastic molded parts on rubber gaskets, after injection molding on the substrate to make an integrated product, the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of subsequent processes easier.

- Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the molding reliability of the composite product is higher. .

- Choose appropriate resin and molding conditions, that is, for products that are easily deformed and damaged (such as glass, coils, electrical parts, etc.), they can also be sealed and fixed by resin.

- Choose an appropriate mold structure, and the insert product can also be completely enclosed in the resin.

- The combination of a vertical injection molding machine, a manipulator, and an insert product alignment device, etc., most of the insert molding process can realize automated production.

- After the insert is molded, it can also be made into products with hollow grooves after core hole processing.

Injection Molded Plastic Parts Advantages

The advantages of injection plastic mold parts are fast manufacturing speed, high efficiency, operation can be automated, variety of colors, shapes can be from simple to complex, size can be from large to small, and the size of the product is accurate, the product is easy to update, and it can be made into complex shapes. Parts and injection molding are suitable for mass production and molding processing fields such as products with complex shapes.

Injection Moulding Parts Materials We Used

ABS, PC, PP, PS, POM, HDPE ,PMMA, PBT, PVC, PA6, PA66, PA66+30%GF, PTFE,PC+ABS,TPE, Mesin, Nylon, Metal, Acrylic, Polymer Injection Molding Material.

Plastic Injection Molding Parts Surface Treatment

Powder Coating ,Galvanized, Texture, Silk-printing, Vacuum coating, rubber coating, etc.

Application Of Injection Molding Parts

Injection moulded are widely used in custom plastic injection molding parts, automotive molding industry plastic parts, bicycle and motorcycle plastic components, car and vehicle rappid injection molding part, door and windows and furniture, household appliance, gas meter, power tool,LED lighting, medical instrument plastic injection molding parts, etc.

Why Choose Us

1. One-stop service for plastic parts : drawings–prototype –plastic mold manufacturing–injection production–surface treatment–assembly service.

2. With 90T-850T injection moulding machine ,

3. Develop Mold ,could make sure shorter leading time.

4. IS9001 Certed with strict Quality Control System