Internal Die Casting Defects

1. Gas Porosity

This happens when bubbles form in the cast process after the liquid metal has been cooled. Alumimu die casting parts with gas porosities look like round or oval structures with smooth, bright white or yellow surfaces. When a result, gas trapped within the solid metal develops bubbles or holes as the cast cools. This usually happens when the cast is getting hard, and you may see some holes in the cast. It depends on how bad the gas porosity is. It can lead to other flaws and a higher scrap rate.

Defect Causes

- Liquefied Metal Release Hydrogen—Most of the time, hydrogen dissolves better in molten metal alloys when the melting temperature is higher. When die-casting, the metal cools and hardens, which makes hydrogen less soluble and lets it escape from the molten metal. As a result, gas porosities occur.

- Gas Present During the Filling Process—In the high pressure die casting process, the molten metal alloy is poured quickly and under a lot of pressure into molds. So, turbulences can happen if the liquid alloy doesn’t move steadily, which can lead to gas porosities.

- Mold Releasing Agents Give Off Gases—Mold releasing agents usually break down and give off gases when the molten metal alloy heats them. Because of this, too much use of mold-releasing agents can lead to gas volatilization.

Possible Solutions

- Prevent air from getting to the molten metal and control the melting process by melting the raw material in a vacuum or near a low-solubility gas.

- Make sure you have a metal alloy ingot that is clean and dry.

- Use clear parameters for die casting, such as the injection speed.

- A long enough sprue and a runner will help the molten metal flow steadily and let the gases out easily.

- Choose mold-releasing agents that are of good quality and use the right amount.

- To use our self–developed squeeze casting process. In this process, molten metal is injected into the dies under high pressure with minimum turbulence to avoid the formation of porosity inside the castings.

2. Inclusions

These are holes with odd shapes inside or on the surface of the casting. In a metal casting with inclusions, there are bits of sand, rubbish, material, or a byproduct of deoxidation that don’t belong there. Inclusions can affect how a metal casting works mechanically, and you can use UT or X-rays to find them.

Defect Causes

- Impurities in the metal because you failed to clean it well or because it was near the garbage.

- Low purity of the furnace charge.

- How the metal reacts with the air around it or the mold’s surface.

- When mold release agents have too much graphite in them.

Possible Solutions

- Make sure the charge in the furnace is clean.

- Cleans the liquid metal the right way by getting rid of all slags.

- Clean the inside of the die and the ladles well.

- If mold-release agents have graphite, make sure they are mixed and stirred evenly.

3. Shrinkage Porosity

When die casting, shrinkage porosity happens when the metal cools and solidifies. There are three kinds of shrinkage porosity: open shrinkage, closed shrinkage, and warping. Each of these changes the stress of the metal. This flaw shows up as edges that aren’t smooth and may also have cracks or dendritic fractures.

Defect Causes

- You made the cooling system wrong.

- Opening the mold prematurely.

- Using a pouring temperature that is very high.

Possible Solutions

- Fix the structure of the casting as a whole.

- Change the running (gate) system to have risers that allow molten metal to flow continuously.

- Put internal chills, cooling coils, or ribs in to help get rid of more heat.

- Change the temperature of the casting to cut down on total volume losses.

Superficial Die Casting Defects

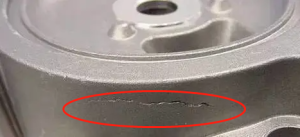

1. Cracks

Stress inside and outside the material causes fissures. Die castings have irregular or straight lines. The first crack emerges during cooling and hardening.Cavity-shaped materials can’t shrink naturally. Residual stress cracks or deforms the mold—the second type of crack results from external force. Cutting or molding forces cause the forces. Poor alloy mixing causes cracks. Use the right parts for melting the alloy. Improving the part’s construction and ensuring uniform wall thickness can also prevent this problem. Die casting machine ejection can also repair this casting defect.

2. Network Cracks

Die cast parts with network cracks have hairlike depressions and bumps. Die protrusion increases with casting time. If the die cavity isn’t smooth, the filling temperature is too high, the casting material is wrong, or the heat treatments are wrong, it can happen. Good die casting mold material and heat treatment can prevent this defect. Ensure the mold heats uniformly and enough to remove internal stress. You should balance the die cavity temperature with proper cooling. Die casting requires a smooth surface. Polish the die cavity and gating system regularly.

3. Flashes

Due to this flaw, the part made by die casting has thin, irregularly shaped metal sheets. Some things that can cause it are a fast injection speed, a high filing temperature, rubbish on the cutting edge and not enough pressure on the die. You must use the correct processing parameters to avoid this defect and keep your dies in good shape.

4. Cold Shut

The cast contains directional lines. Thin, smooth lines may grow with outside factors. Cold shut defects occur when die cavity liquid metal fronts don’t merge properly. Therefore, the component is weaker. Low molten temperature, sluggish injection speed, an inappropriately constructed gating system, and a poor-flowing alloy can cause a cold shut. This defect is visible. Raising the mold and molten metal temperatures can prevent cold shuts. Change the game’s size, placement, and plunger speed.

5. Drags and Soldering

Drags are faults that open with the die—long, narrow scratches on cast pieces. Die cavity and metal alloy cling together after soldering. Some parts look too full or empty. Too hot molten alloy, damaged die cavity surface, or insufficient draft angles create errors in pressure die casting. Bad injection mechanisms or mold release agents can also cause these issues. Use good releasing agents and the proper ejection system to fix the damaged die cavity surfaces. Change the gate direction to preserve die cores.

6. Blisters

Die casting is done by compressing air in the machine and employing a vacuum valve, overflow, or exhaust. Air left inside molten metal will dissolve equally. Air becomes compressed during turbulences, generating a blister.This fault is buried in low-temperature pressure die casting, which weakens the product. High temperatures cause surface bubbles. Die-casting parameters must be correct. Check your gating system to ensure proper venting.

7. Flow Marks

These are stripes and non-directional lines on a die-cast part that are different in color from the base. Liquid metal entering the cavity often produces a thin, incomplete coating. The filling leaves traces. Low die temperature, excess lubricant, low filling pressure, mold release agent, and small cross-section area generate flow markings. Increase die temperature, injection speed, and other casting parameters.

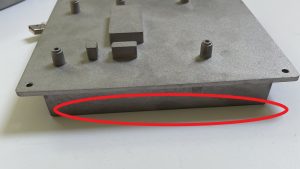

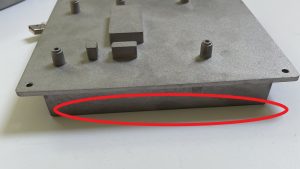

8. Deformation

This happens when the drawn part is different from the shape of the finished part. Deformation occurs when you fail to take the gate off properly and do not design the cast well. Also, if the mold opens too soon, the ejection mechanisms aren’t good enough, or if you take out the casting drags. So, you must choose a good way to open the gate. Also, change the time when the mold opens to ensure rigidity. You can also avoid this defect by optimizing structural castings’ designs and eliminating unfavorable demolding factors.

End Thoughts

Understanding aluminum die casting defects causes and solutions is critical to the quality of the parts produced. You need to learn many things, so it is best to work with an expert in aluminum die casting. CEX Casting has more than 20 years manufacturing experience in aluminum die casting.With our squeeze casting-a superior die casting process, most of those die casting defects could be avoided. Contact us today if you want to learn more.